Difference between revisions of "Electron Detector"

| (38 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

| + | == Qweak Run 2 preparation == | ||

| + | * [http://hallcweb.jlab.org/polwiki/images/0/08/MeanResponseQWADv3.pdf ''characterize all v3 QWADs by giving calibration input signal''] | ||

| + | * ''Verify each program step of the motion mechanism'' | ||

| + | * ''install QWADs for all detector planes:'' | ||

| + | Beam Left : QWAD10 QWAD04 QWAD02 QWAD03 | ||

| + | Detector plane: p1 p2 p3 p4 | ||

| + | Beam Right : QWAD05 QWAD06 QWAD08 QWAD09 | ||

| + | * ''clamp ribbon cable's ground-shield to the vacuum-can'' | ||

| + | * ''prepare DAQ for data taking (reinstating to the run-1 status)'' | ||

| + | * ''cross-check the cable-labels'' | ||

| + | * DAQ tests | ||

| + | ** check chip-scope view of the LVDS response | ||

| + | ** reason for appearance of 255's | ||

| + | ** check for 'missing events' in the overlap region | ||

| + | ** vary involved parameter and check responses. | ||

| + | * update the wiki page | ||

| + | ** for emergency response | ||

| + | ** for information related to the subsystem | ||

| + | |||

| + | ''Italics'': represents completed | ||

| + | '''General Font''': still to be done | ||

| + | |||

== Standard Running Procedure == | == Standard Running Procedure == | ||

| − | |||

| − | |||

| − | |||

| − | + | * from any cdaq machine, from the directory ~/compton/ execute '''StripTool edetectorEpics.stp''' . This pulls up the strip chart of some relevant epics variables for e-detector. If we are unable to locate this file, the following epics variables should be explicitly opened. | |

| − | |||

| − | |||

| − | * from any cdaq machine, from the directory ~/compton/ execute '''StripTool edetectorEpics.stp''' . This pulls up the strip chart of some relevant epics variables for e-detector. If | ||

** 4 Hall-C Chicane BPMs | ** 4 Hall-C Chicane BPMs | ||

*** 3P01A (IPM3P01A.XPOS , IPM3PO1A.YPOS) | *** 3P01A (IPM3P01A.XPOS , IPM3PO1A.YPOS) | ||

| Line 14: | Line 30: | ||

*** 3P03A (IPM3P03A.XPOS , IPM3PO3A.YPOS) | *** 3P03A (IPM3P03A.XPOS , IPM3PO3A.YPOS) | ||

** Rates on Scintillator (cComptScintRateNorm) on the Compton laser table, along with Photon detector Rates (cComptPhotonRateNorm) | ** Rates on Scintillator (cComptScintRateNorm) on the Compton laser table, along with Photon detector Rates (cComptPhotonRateNorm) | ||

| + | * Turn on the HV on the e-detector planes. (Current operating voltage: plane-2: -260V, plane-3: -360V, plane-4: -360V) | ||

| − | + | Request beam to be set through the chicane, with FFB turned ON | |

| − | * Check Chicane view: on any cdaq machine type | + | * Check Chicane view: on any cdaq machine type ''edmmonticello'', from the ''Monticello'' screen |

| − | ** open | + | ** open ''Magnets'' -> ''Magnet Commander'' |

| − | *** | + | *** ''3C'' -> ''Compton Combo'' |

| − | *** In this | + | *** In this ''Hall C Compton Control'' screen, the ''REQUESTED'' and ''ACTUAL'' current readbacks should be ~104 A |

| − | ** open | + | ** open ''BPM'' -> ''BPM Overview'' |

| − | *** open | + | *** open ''Absolute'' -> on the Hall C column from the left bottom of this screen |

| − | *** BPM | + | *** BPM ''3P01A'', ''3P02A'', ''3P02B'' and ''3P03A'' should have finite non-zero read back |

| − | * Check compton rates from the photon detector (typically 600 per uA per second) | + | * Check compton rates from the photon detector (typically 600 per uA per second ?) |

| − | ** | + | ** If the Scintillator rates are too high (> 2000 Hz/uA), '''DO NOT''' proceed without talking to the Compton-on-call |

** The Fast feedback has been observed to give lower background rate, the status of FFB can be checked on the HALL-C general tools screen on the main-monitor of HALL-C | ** The Fast feedback has been observed to give lower background rate, the status of FFB can be checked on the HALL-C general tools screen on the main-monitor of HALL-C | ||

| + | ---- | ||

| + | |||

| + | ==Backout Procedure== | ||

| + | https://hallcweb.jlab.org/polwiki/index.php/E-Detector_Motion_System#Parking_the_detector | ||

| + | |||

| + | ---- | ||

| + | |||

| + | ==Diamond strip electron detector== | ||

| + | <!-- ==[[Test Box]]== --> | ||

| + | The electron detector in use is a 21mm x 21mm CVD diamond microstrip. We are using 4 planes of the above detector for coincidence measurement. Each of the 4 planes are separated by ~ 1cm with the strips of each plane aligned to ~ 20 µm. Each plane contains 96 horizontal diamond strips (polycrystalline CVD diamond). Each strip is 180 µm wide and they are separated by a 20 µm gap. Metalization was done on each plane with Titanium-Platinum-Gold (TiPtAu). The carrier boards are in Ceramic (alumina). | ||

| + | [[Image:El det diamond.png|700px]] | ||

| − | + | The way we had to connect the flex cables to the QWAD boards, we lose the first 4 strips of the detector to the QWAD and Flex grounds. Hence the strip # 5 reaches that QWAD pin which should have received strip # 1, hence the Data acquisition treats the 5th strip as strip # 1. In order to avoid confusion and repetative explanation, in all plots generated, we just treat as if the detector has strips starting from position of 5th strip and the position of the compton-edge as spotted in the spectrum is appropriately corrected. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | == | + | === Technical Diagram === |

| − | == | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | Following is the design layout of the diamond micro-strip detectors: | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | [[Image:EDet front schematic.JPG]] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | <!-- == [[Shielded Flex Cables]] ==(narayan, !! notice that this link still exists and to do it neatly I should redirect that link to this position, left for later --> | |

| − | + | <!-- this is comment format--> | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | == Q-Weak Amplifier Discriminator == | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | The Q-Weak Amplifier Discriminator, termed as QWAD has 48 channels on each electronic board. We would be using 2 QWAD boards per plane. One QWAD will process the signal from all odd strips of the detector, while another processing the signals from all even strips. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | Though functionally the board is capable of operation in both positive as well as negative polarity. We shall be using it in negative polarity with the jumpers on the inner side of each channel ([[Media:QWAD.png| diagram elaborating jumper placement]]) | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | : | ||

| − | + | '''Qweak RUN-1 scenario''' | |

| + | The QWAD (version-2) being used requires +5,-5 and two GND connections for its power supply. We are using two Agilent E3633A LV [[http://hallcweb.jlab.org/polwiki/index.php/Low_Voltage_Power_supply_for_QWAD power supply]] to provide the same. The QWAD boards would be attached to the vacuum - can in the tunnel whereas the power supply needs to be behind the Green Wall (2nd rack allocated), which adds a long cable of ~120 feet between the power supply and the consumer QWAD boards. We are using a 5 conductor 12 AWG cable for carrying 8 x 1.6A (~13A) from one power supply unit delivering +5V and 8 x 0.37A (~3A) from another unit delivering -5V. We use a 22 AWG cable for sensing the voltage at the load. A terminal block is used to send out this voltage to all of the 8 QWAD boards. | ||

| + | Noise measurements after installation of QWADs with HV turned ON to -250V on the detector planes 2, 3 and 4 can be seen on the [[Media:Installed QWAD noise rates.pdf |current noise rates]] | ||

| − | + | '''Qweak RUN-2 scenario''' | |

| − | + | We have received 11 QWAD boards (version-3) at JLab. All of these boards were checked for expected functionality on each channel along with a quick noise check (at TRIUMF). | |

| − | + | * QWAD07 has some problem in channel-17 | |

| − | * | + | * QWAD10: still have the threshold values as found from TRIUMF |

| − | + | * QWAD11: still have the threshold values as found from TRIUMF | |

| − | : | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | == | + | ==Low Voltage Power supply for QWAD== |

| − | + | <!-- == [[Low Voltage Power supply for QWAD]] (narayan, !! notice that this link still exists and to do it neatly I should redirect that link to this position, left for later ==--> | |

| − | + | ||

| − | + | The QWAD utilizes 3 different power supplies. For the main power input, we use Acopian 5 V supply. This has a small voltage adjustment screw on the back panel. They are behind the green wall in the rack HC01Z02. The lowest of these is used for +5V and the one above for -5V to the QWAD. The supply used for +5V has a blown LED hence the even though it is turned ON, a casual look may suggest that it is turned off. These two Acopian supplies have their ground connected at the supply itself. The actual connections are made on the back panel. This power supply takes the mainline power from its back plane using a screw-nut arrangement, rather than a standard plug. Caution is needed while working there. | |

| − | + | ||

| + | We are using Agilent 3633A for setting the external threshold of the QWAD. In the current mode it can deliver a maximum output of 8.0 V. If one indeed wants to go to higher values. The output should be brought down to 0V, then turning the output off. With the output being off, the set voltage may be set to (a maximum of) 9.0 V ; after which the output can be turned on again. | ||

| + | |||

| + | The Agilent power supply used for external threshold can be remotely accessed via the port 11 on hall C terminal server 5. One can access this by the command from any cdaq machine: | ||

| + | telnet hctsv5 2011 | ||

| + | Next, the telnet prompt by pressing Ctrl + ] | ||

| + | at the telnet prompt explicitly set the line mode on the terminal | ||

| + | telnet> | ||

| + | telnet> mode line | ||

| + | |||

| + | One may find detailed instruction for accessing it remotely via the RS232 connection in the manual ([[Media:Agilent_E3634A.pdf|User Guide]]). | ||

| + | |||

| + | <!-- == [[e-Detector Motion System]] == --> | ||

| + | ==Motion controller== | ||

| + | For moving the e-detector to running position or to garage, first open the GUI which can help us do it remotely | ||

| + | * login to cdaql* as cvxwrks | ||

| + | * cd MEDM/compton | ||

| + | * edm -x HLC_E_CompED.edl | ||

| + | |||

| + | [[Image:Edet_parked.png]] | ||

| + | |||

| + | Before any motion on the e-detector is attempted, request MCC to have '''beam OFF''' and mask Compton electron detector motion FSD. There is no visual verification of this FSD on the motion GUI, so please confirm the masking before moving the detector. | ||

| + | |||

| + | === Parking the detector === | ||

| + | For taking the e-detector out of beam, it needs to be parked. | ||

| + | '''When to Park''' | ||

| + | # If we expect pulsed beam in order to re-established beam path after beam studies or a long downtime | ||

| + | # If we are sure of not running for a couple of days at a stretch | ||

| + | # If the beam is intended to be taken straight through (instead of the chicane) | ||

| − | + | '''How to Park''' | |

| − | + | # Ensure beam is off and get the Compton electron detector motion FSD masked by requesting MCC. | |

| − | ---- | + | # From the drop-down menu-1 (on the left-middle of the e-detector motion GUI), select the '''Garage''' and the detector starts going to Garage. |

| + | # On completion of this motion, the yellow highlighting goes away and the detector is well parked (out of beam) now. | ||

| − | + | The above snapshot of the GUI is at a time when the detector was in Garage, so the above diagram is a good reference for this position. Inform MCC that the detector is Garaged and request the Compton electron detector motion FSD to be unmasked. It is safe to take beam now. | |

| + | ''''BEAM' position''' | ||

| + | While taking Compton production data, the e-detector needs to be in the 'BEAM' position. In this positions, the detector is a few millimeter away from the beam. | ||

| − | + | (The 'BEAM' position stands for the vertical position of the e-detector at 8.7890 from its 'HOME' and this can be checked by the EPICS variable HCCEDPOS) | |

| + | ===How to move to 'BEAM' position=== | ||

| + | This should preferably be done by an expert, or if you have been requested to do so by an expert | ||

| − | == | + | # Ensure beam is off and get the Compton electron detector motion FSD masked by requesting MCC. (The detector is most probably in Garage, when you start here) |

| + | # On the top drop-down menu-1 select '''Go HOME'''. (The detector would start moving towards its predefined HOME position) | ||

| + | # Once the above motion is complete (the yellow highlighting turns off), and you are at HOME you can see '''X=0.0000''' on the top left corner of the GUI. Now, select '''Go Pos 2''' from drop-down menu-1. | ||

| + | # At the end of this motion, the vertical position reader would now show '''X=8.6890'''. Check the Vertical Position Readback to confirm the position and inform MCC further requesting to unmask the corresponding FSD. | ||

| + | YOUR ARE DONE! | ||

| + | The following snapshot shows the motion GUI with the detector in standard running position. | ||

| − | + | [[Image:Edet running position.png]] | |

| + | NOTE: | ||

| + | # The GUI's vertical motion view is counter-intuitive | ||

| + | # HOME is not the same as 'OUT OF BEAM' | ||

| + | # 'BEAM' position is not a position of the detector in direct beam | ||

| − | == | + | ===Identifying an unresponsive motion controller=== |

| + | If the e-detector motion GUI shows a red color in "Comm" box. The GUI is possibly frozen. Following is a | ||

| + | [[Image:Edet motionGUI forzen.png]] | ||

| − | + | In this state, an expert should be contacted. The detector GUI may not work without the intervention of Dave Gaskell since this GUI runs on the Moller IOC which is managed by him. In case the detector GUI freezes while the detector was attempted to be moved, then beam can be taken only after ensuring that the detector is out of beam (by physically running 'program 3' locally from the motion controller in the Hall). | |

| + | === Experts to Call === | ||

| + | In case the motion controller is not responding, please call one of the following experts in the given order: | ||

| + | # Amrendra Narayan (Cell # 662-617-4256, Google # 757-952-6126) | ||

| + | # David Gaskell | ||

| + | # Arshak (Yerevan collaboration) | ||

== [[e-Detector Assembly]] == | == [[e-Detector Assembly]] == | ||

| + | |||

| + | <!-- == [[e-Detector High Voltage]] ==--> | ||

| + | ==High Voltage== | ||

| + | We use an NHQ 202L HV power supply to give HV to the diamond micro strip detectors. Continuing with Qweak run-1 operating value, we intend to operate the detectors at -400V. The module is set to deliver negative voltage through a turn-switch on its side. This is not visible on the front panel. The actual value of the voltage can be set by the front panel knob or remotely. If the module is intend to be operated remotely. the DAC flip-switch should be flipped away from the knob. | ||

| + | |||

| + | This module is connected to port server hctsv4 at port 3. In order to connect to the device once has to execute frm any cdaql* terminal. | ||

| + | telnet hctsv4 2003 | ||

| + | |||

| + | This can be followed by following commands as found in the NHQ202L manual. | ||

| + | |||

| + | ==Cables and Connections== | ||

| + | {| style="color:maroon; background-color:#ffffff;" cellpadding="10" cellspacing="0" border="1" | ||

| + | ! Plane # | ||

| + | ! Slave # | ||

| + | ! Cable # | ||

| + | |- | ||

| + | | 4 | ||

| + | | 1 | ||

| + | | 28 | ||

| + | |- | ||

| + | | 4 | ||

| + | | 2 | ||

| + | | 22 | ||

| + | |- | ||

| + | | 4 | ||

| + | | 3 | ||

| + | | 18 | ||

| + | |- | ||

| + | | 3 | ||

| + | | 1 | ||

| + | | 25 | ||

| + | |- | ||

| + | | 3 | ||

| + | | 2 | ||

| + | | 21 | ||

| + | |- | ||

| + | | 3 | ||

| + | | 3 | ||

| + | | 17 | ||

| + | |- | ||

| + | | 2 | ||

| + | | 1 | ||

| + | | 24 | ||

| + | |- | ||

| + | | 2 | ||

| + | | 2 | ||

| + | | 20 | ||

| + | |- | ||

| + | | 2 | ||

| + | | 3 | ||

| + | | 16 | ||

| + | |- | ||

| + | | 1 | ||

| + | | 1 | ||

| + | | 27 | ||

| + | |- | ||

| + | | 1 | ||

| + | | 2 | ||

| + | | 23 | ||

| + | |- | ||

| + | | 1 | ||

| + | | 3 | ||

| + | | 19 | ||

| + | |} | ||

| + | |||

| + | ''Courtesy: The above map was noted down by Arshak'' | ||

Latest revision as of 05:22, 27 February 2012

Qweak Run 2 preparation

- characterize all v3 QWADs by giving calibration input signal

- Verify each program step of the motion mechanism

- install QWADs for all detector planes:

Beam Left : QWAD10 QWAD04 QWAD02 QWAD03 Detector plane: p1 p2 p3 p4 Beam Right : QWAD05 QWAD06 QWAD08 QWAD09

- clamp ribbon cable's ground-shield to the vacuum-can

- prepare DAQ for data taking (reinstating to the run-1 status)

- cross-check the cable-labels

- DAQ tests

- check chip-scope view of the LVDS response

- reason for appearance of 255's

- check for 'missing events' in the overlap region

- vary involved parameter and check responses.

- update the wiki page

- for emergency response

- for information related to the subsystem

Italics: represents completed General Font: still to be done

Standard Running Procedure

- from any cdaq machine, from the directory ~/compton/ execute StripTool edetectorEpics.stp . This pulls up the strip chart of some relevant epics variables for e-detector. If we are unable to locate this file, the following epics variables should be explicitly opened.

- 4 Hall-C Chicane BPMs

- 3P01A (IPM3P01A.XPOS , IPM3PO1A.YPOS)

- 3P02A (IPM3P02A.XPOS , IPM3PO2A.YPOS)

- 3P02B (IPM3P02B.XPOS , IPM3PO2B.YPOS)

- 3P03A (IPM3P03A.XPOS , IPM3PO3A.YPOS)

- Rates on Scintillator (cComptScintRateNorm) on the Compton laser table, along with Photon detector Rates (cComptPhotonRateNorm)

- 4 Hall-C Chicane BPMs

- Turn on the HV on the e-detector planes. (Current operating voltage: plane-2: -260V, plane-3: -360V, plane-4: -360V)

Request beam to be set through the chicane, with FFB turned ON

- Check Chicane view: on any cdaq machine type edmmonticello, from the Monticello screen

- open Magnets -> Magnet Commander

- 3C -> Compton Combo

- In this Hall C Compton Control screen, the REQUESTED and ACTUAL current readbacks should be ~104 A

- open BPM -> BPM Overview

- open Absolute -> on the Hall C column from the left bottom of this screen

- BPM 3P01A, 3P02A, 3P02B and 3P03A should have finite non-zero read back

- open Magnets -> Magnet Commander

- Check compton rates from the photon detector (typically 600 per uA per second ?)

- If the Scintillator rates are too high (> 2000 Hz/uA), DO NOT proceed without talking to the Compton-on-call

- The Fast feedback has been observed to give lower background rate, the status of FFB can be checked on the HALL-C general tools screen on the main-monitor of HALL-C

Backout Procedure

https://hallcweb.jlab.org/polwiki/index.php/E-Detector_Motion_System#Parking_the_detector

Diamond strip electron detector

The electron detector in use is a 21mm x 21mm CVD diamond microstrip. We are using 4 planes of the above detector for coincidence measurement. Each of the 4 planes are separated by ~ 1cm with the strips of each plane aligned to ~ 20 µm. Each plane contains 96 horizontal diamond strips (polycrystalline CVD diamond). Each strip is 180 µm wide and they are separated by a 20 µm gap. Metalization was done on each plane with Titanium-Platinum-Gold (TiPtAu). The carrier boards are in Ceramic (alumina).

The way we had to connect the flex cables to the QWAD boards, we lose the first 4 strips of the detector to the QWAD and Flex grounds. Hence the strip # 5 reaches that QWAD pin which should have received strip # 1, hence the Data acquisition treats the 5th strip as strip # 1. In order to avoid confusion and repetative explanation, in all plots generated, we just treat as if the detector has strips starting from position of 5th strip and the position of the compton-edge as spotted in the spectrum is appropriately corrected.

Technical Diagram

Following is the design layout of the diamond micro-strip detectors:

Q-Weak Amplifier Discriminator

The Q-Weak Amplifier Discriminator, termed as QWAD has 48 channels on each electronic board. We would be using 2 QWAD boards per plane. One QWAD will process the signal from all odd strips of the detector, while another processing the signals from all even strips.

Though functionally the board is capable of operation in both positive as well as negative polarity. We shall be using it in negative polarity with the jumpers on the inner side of each channel ( diagram elaborating jumper placement)

Qweak RUN-1 scenario The QWAD (version-2) being used requires +5,-5 and two GND connections for its power supply. We are using two Agilent E3633A LV [power supply] to provide the same. The QWAD boards would be attached to the vacuum - can in the tunnel whereas the power supply needs to be behind the Green Wall (2nd rack allocated), which adds a long cable of ~120 feet between the power supply and the consumer QWAD boards. We are using a 5 conductor 12 AWG cable for carrying 8 x 1.6A (~13A) from one power supply unit delivering +5V and 8 x 0.37A (~3A) from another unit delivering -5V. We use a 22 AWG cable for sensing the voltage at the load. A terminal block is used to send out this voltage to all of the 8 QWAD boards. Noise measurements after installation of QWADs with HV turned ON to -250V on the detector planes 2, 3 and 4 can be seen on the current noise rates

Qweak RUN-2 scenario We have received 11 QWAD boards (version-3) at JLab. All of these boards were checked for expected functionality on each channel along with a quick noise check (at TRIUMF).

- QWAD07 has some problem in channel-17

- QWAD10: still have the threshold values as found from TRIUMF

- QWAD11: still have the threshold values as found from TRIUMF

Low Voltage Power supply for QWAD

The QWAD utilizes 3 different power supplies. For the main power input, we use Acopian 5 V supply. This has a small voltage adjustment screw on the back panel. They are behind the green wall in the rack HC01Z02. The lowest of these is used for +5V and the one above for -5V to the QWAD. The supply used for +5V has a blown LED hence the even though it is turned ON, a casual look may suggest that it is turned off. These two Acopian supplies have their ground connected at the supply itself. The actual connections are made on the back panel. This power supply takes the mainline power from its back plane using a screw-nut arrangement, rather than a standard plug. Caution is needed while working there.

We are using Agilent 3633A for setting the external threshold of the QWAD. In the current mode it can deliver a maximum output of 8.0 V. If one indeed wants to go to higher values. The output should be brought down to 0V, then turning the output off. With the output being off, the set voltage may be set to (a maximum of) 9.0 V ; after which the output can be turned on again.

The Agilent power supply used for external threshold can be remotely accessed via the port 11 on hall C terminal server 5. One can access this by the command from any cdaq machine:

telnet hctsv5 2011

Next, the telnet prompt by pressing Ctrl + ] at the telnet prompt explicitly set the line mode on the terminal

telnet> telnet> mode line

One may find detailed instruction for accessing it remotely via the RS232 connection in the manual (User Guide).

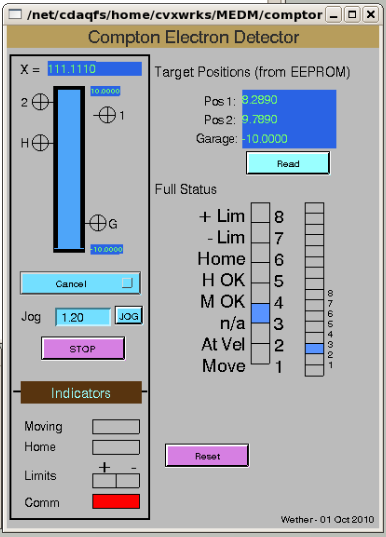

Motion controller

For moving the e-detector to running position or to garage, first open the GUI which can help us do it remotely

- login to cdaql* as cvxwrks

- cd MEDM/compton

- edm -x HLC_E_CompED.edl

Before any motion on the e-detector is attempted, request MCC to have beam OFF and mask Compton electron detector motion FSD. There is no visual verification of this FSD on the motion GUI, so please confirm the masking before moving the detector.

Parking the detector

For taking the e-detector out of beam, it needs to be parked.

When to Park

- If we expect pulsed beam in order to re-established beam path after beam studies or a long downtime

- If we are sure of not running for a couple of days at a stretch

- If the beam is intended to be taken straight through (instead of the chicane)

How to Park

- Ensure beam is off and get the Compton electron detector motion FSD masked by requesting MCC.

- From the drop-down menu-1 (on the left-middle of the e-detector motion GUI), select the Garage and the detector starts going to Garage.

- On completion of this motion, the yellow highlighting goes away and the detector is well parked (out of beam) now.

The above snapshot of the GUI is at a time when the detector was in Garage, so the above diagram is a good reference for this position. Inform MCC that the detector is Garaged and request the Compton electron detector motion FSD to be unmasked. It is safe to take beam now.

'BEAM' position While taking Compton production data, the e-detector needs to be in the 'BEAM' position. In this positions, the detector is a few millimeter away from the beam.

(The 'BEAM' position stands for the vertical position of the e-detector at 8.7890 from its 'HOME' and this can be checked by the EPICS variable HCCEDPOS)

How to move to 'BEAM' position

This should preferably be done by an expert, or if you have been requested to do so by an expert

- Ensure beam is off and get the Compton electron detector motion FSD masked by requesting MCC. (The detector is most probably in Garage, when you start here)

- On the top drop-down menu-1 select Go HOME. (The detector would start moving towards its predefined HOME position)

- Once the above motion is complete (the yellow highlighting turns off), and you are at HOME you can see X=0.0000 on the top left corner of the GUI. Now, select Go Pos 2 from drop-down menu-1.

- At the end of this motion, the vertical position reader would now show X=8.6890. Check the Vertical Position Readback to confirm the position and inform MCC further requesting to unmask the corresponding FSD.

YOUR ARE DONE! The following snapshot shows the motion GUI with the detector in standard running position.

NOTE:

- The GUI's vertical motion view is counter-intuitive

- HOME is not the same as 'OUT OF BEAM'

- 'BEAM' position is not a position of the detector in direct beam

Identifying an unresponsive motion controller

If the e-detector motion GUI shows a red color in "Comm" box. The GUI is possibly frozen. Following is a

In this state, an expert should be contacted. The detector GUI may not work without the intervention of Dave Gaskell since this GUI runs on the Moller IOC which is managed by him. In case the detector GUI freezes while the detector was attempted to be moved, then beam can be taken only after ensuring that the detector is out of beam (by physically running 'program 3' locally from the motion controller in the Hall).

Experts to Call

In case the motion controller is not responding, please call one of the following experts in the given order:

- Amrendra Narayan (Cell # 662-617-4256, Google # 757-952-6126)

- David Gaskell

- Arshak (Yerevan collaboration)

e-Detector Assembly

High Voltage

We use an NHQ 202L HV power supply to give HV to the diamond micro strip detectors. Continuing with Qweak run-1 operating value, we intend to operate the detectors at -400V. The module is set to deliver negative voltage through a turn-switch on its side. This is not visible on the front panel. The actual value of the voltage can be set by the front panel knob or remotely. If the module is intend to be operated remotely. the DAC flip-switch should be flipped away from the knob.

This module is connected to port server hctsv4 at port 3. In order to connect to the device once has to execute frm any cdaql* terminal.

telnet hctsv4 2003

This can be followed by following commands as found in the NHQ202L manual.

Cables and Connections

| Plane # | Slave # | Cable # |

|---|---|---|

| 4 | 1 | 28 |

| 4 | 2 | 22 |

| 4 | 3 | 18 |

| 3 | 1 | 25 |

| 3 | 2 | 21 |

| 3 | 3 | 17 |

| 2 | 1 | 24 |

| 2 | 2 | 20 |

| 2 | 3 | 16 |

| 1 | 1 | 27 |

| 1 | 2 | 23 |

| 1 | 3 | 19 |

Courtesy: The above map was noted down by Arshak