Difference between revisions of "2-pass commissioning"

From HallCWiki

Jump to navigationJump to search (Created page with "== Beam Commissioning at 2-pass for Fall 2019 == === Beam checkout === === Detector checkout and calibrations ===") |

|||

| Line 1: | Line 1: | ||

== Beam Commissioning at 2-pass for Fall 2019 == | == Beam Commissioning at 2-pass for Fall 2019 == | ||

=== Beam checkout === | === Beam checkout === | ||

| + | |||

| + | For polarized 3He running in Fall 2019 and Spring 2020, the nominal raster for production is 5mm diameter circular. | ||

| + | |||

| + | === Establish beam in the hall === | ||

| + | ''' Goals ''' | ||

| + | - Using empty target location, make sure beam reaches beam dump without hitting anything. | ||

| + | |||

| + | === Initial Raster checks === | ||

| + | ''' Goals ''' | ||

| + | - Establish beam to be roughly centered in beam pipe by locating it on [[Hall_C_YAG_Viewer |YAG viewer]] just upstream of target. | ||

| + | - Turn on Raster and verify beam profile expands as expected. | ||

| + | |||

| + | |||

| + | - Beam Current: Viewer limited (Tune Beam) | ||

| + | - Target: Empty | ||

| + | - Raster: Off; 5mm diameter | ||

| + | |||

| + | '''Procedure''' | ||

| + | - Insert YAG viewer on Hall C superharp girder | ||

| + | - start with raster off, verify beam spot roughly centered | ||

| + | - if the beam energy has changed, check that on the Hall C Raster Control GUI it is initialized for the correct beam energy (at the top of the GUI). | ||

| + | - request raster on: 2mm x 2mm | ||

| + | - watch beam spot on viewer and verify Raster's basic functionality | ||

| + | - Retract viewer | ||

| + | |||

| + | === Harp scans === | ||

| + | ''' Goals ''' | ||

| + | -Verify operation of Harp scanners w/ beam. | ||

| + | - Establish acceptable beam profile (nominal 100--500um sigma) | ||

| + | |||

| + | - Beam Current: 5 uA CW | ||

| + | - Target: Empty | ||

| + | - Raster: Off | ||

| + | |||

| + | '''Procedure''' | ||

| + | - Verify that the raster is OFF for the harp scans at the target (3H07) | ||

| + | - Ask for harp scans with IHA3H07A and IHA3H07B | ||

| + | - verify beam profile (nominal 100--500um sigma) on at least one scanner on Hall C upstream beamline (good to check 3H07A/B) | ||

| + | |||

| + | === Target/Beam centering, Raster calibration === | ||

| + | ''' Goals ''' | ||

| + | - Establish beam position on target, check/confirm raster size | ||

| + | |||

| + | - Beam Current: 5--10 uA CW | ||

| + | - Target: Double Carbon Hole | ||

| + | |||

| + | '''Procedure''' | ||

| + | - Note: DAQs should be running and double carbon hole target is in place | ||

| + | - Online shift crew will proceed with program below. | ||

| + | |||

| + | - Attempt to view beam on BeO (if available in target ladder) ** NOT available in current target configuration (2017--2020) ** | ||

| + | - Target: BeO | ||

| + | - Current: 5 uA CW | ||

| + | - Raster: OFF | ||

| + | - Target camera: ON | ||

| + | - Target lamp: OFF | ||

| + | - Log camera snapshot of beam spot on BeO | ||

| + | |||

| + | - Image Carbon Hole target using Raster current pickoffs vs. raw trigger rates in SHMS and/or HMS | ||

| + | - NOTE: If there are issues with the raster systems, this step can be skipped provided experts are confident that we know where the beam is on target (ie. good BeO snapshot) | ||

| + | - Target: Double Carbon Hole | ||

| + | - Current: 5 uA CW | ||

| + | - Raster: 5mm diameter | ||

| + | - Run DAQ on SHMS / HMS | ||

| + | - Set prescales to ensure DAQ rate is dominated by scintillator triggers (ie. 3/4) | ||

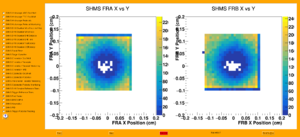

| + | - Run the online analyzer and look at the 'Fast Raster' panel of the online GUI: | ||

| + | - Locate the hole in the 2D intensity histogram. A rough z cut should be included in the script to show up- and down-stream carbon hole separately. | ||

| + | - NOTE: if the beam energy in standard.kinematics is not up to date, the distance scale on the 2D histogram will be wrong | ||

| + | [[File:hallc-carbon-hole.png|thumb]] | ||

| + | - Center Beam on using Double-Carbon-Hole Target: | ||

| + | - Iterate until the hole is clear, and is centered in the circular raster pattern for both up- and donw-stream carbon foils | ||

| + | - Adjust beam position | ||

| + | - Re-run the online analzyer on the new file(s) to see the effect of a raster size change and/or beam position change. Make sure changes are logged in the CODA start-run entries! | ||

| + | - Calibrate raster dimensions against (known, typically 2mm diam.???) Carbon Hole diameter by adjusting Raster magnet settings until raster an appropriate size (RC will know). | ||

| + | |||

=== Detector checkout and calibrations === | === Detector checkout and calibrations === | ||

Revision as of 14:37, 27 November 2019

Beam Commissioning at 2-pass for Fall 2019

Beam checkout

For polarized 3He running in Fall 2019 and Spring 2020, the nominal raster for production is 5mm diameter circular.

Establish beam in the hall

Goals - Using empty target location, make sure beam reaches beam dump without hitting anything.

Initial Raster checks

Goals - Establish beam to be roughly centered in beam pipe by locating it on YAG viewer just upstream of target. - Turn on Raster and verify beam profile expands as expected.

- Beam Current: Viewer limited (Tune Beam) - Target: Empty - Raster: Off; 5mm diameter

Procedure

- Insert YAG viewer on Hall C superharp girder

- start with raster off, verify beam spot roughly centered

- if the beam energy has changed, check that on the Hall C Raster Control GUI it is initialized for the correct beam energy (at the top of the GUI).

- request raster on: 2mm x 2mm

- watch beam spot on viewer and verify Raster's basic functionality

- Retract viewer

Harp scans

Goals -Verify operation of Harp scanners w/ beam. - Establish acceptable beam profile (nominal 100--500um sigma)

- Beam Current: 5 uA CW - Target: Empty - Raster: Off

Procedure - Verify that the raster is OFF for the harp scans at the target (3H07) - Ask for harp scans with IHA3H07A and IHA3H07B - verify beam profile (nominal 100--500um sigma) on at least one scanner on Hall C upstream beamline (good to check 3H07A/B)

Target/Beam centering, Raster calibration

Goals - Establish beam position on target, check/confirm raster size

- Beam Current: 5--10 uA CW - Target: Double Carbon Hole

Procedure - Note: DAQs should be running and double carbon hole target is in place - Online shift crew will proceed with program below.

- Attempt to view beam on BeO (if available in target ladder) ** NOT available in current target configuration (2017--2020) **

- Target: BeO

- Current: 5 uA CW

- Raster: OFF

- Target camera: ON

- Target lamp: OFF

- Log camera snapshot of beam spot on BeO

- Image Carbon Hole target using Raster current pickoffs vs. raw trigger rates in SHMS and/or HMS

- NOTE: If there are issues with the raster systems, this step can be skipped provided experts are confident that we know where the beam is on target (ie. good BeO snapshot)

- Target: Double Carbon Hole

- Current: 5 uA CW

- Raster: 5mm diameter

- Run DAQ on SHMS / HMS

- Set prescales to ensure DAQ rate is dominated by scintillator triggers (ie. 3/4)

- Run the online analyzer and look at the 'Fast Raster' panel of the online GUI:

- Locate the hole in the 2D intensity histogram. A rough z cut should be included in the script to show up- and down-stream carbon hole separately.

- NOTE: if the beam energy in standard.kinematics is not up to date, the distance scale on the 2D histogram will be wrong

- Center Beam on using Double-Carbon-Hole Target:

- Iterate until the hole is clear, and is centered in the circular raster pattern for both up- and donw-stream carbon foils

- Adjust beam position

- Re-run the online analzyer on the new file(s) to see the effect of a raster size change and/or beam position change. Make sure changes are logged in the CODA start-run entries!

- Calibrate raster dimensions against (known, typically 2mm diam.???) Carbon Hole diameter by adjusting Raster magnet settings until raster an appropriate size (RC will know).