2-pass commissioning

From HallCWiki

Revision as of 17:31, 29 November 2019 by Xiaochao (talk | contribs) (→Polarized 3He Cell checkout and commissioning)

Beam Commissioning at 2-pass for Fall 2019

The main purpose of 2-pass commissioning is to establish beam in hall, raster condition, and commission the target. We probably do not need beam energy and BCM calibrations at this stage. No beam polarization is needed.

Beam checkout

For polarized 3He running in Fall 2019 and Spring 2020, the nominal raster for production is 5mm diameter circular. The nominal triggers used are 3/4 for both HMS and SHMS. No coincidence trigger will be used/setup.

Establish beam in the hall

Goals - Using empty target location, make sure beam reaches beam dump without hitting anything.

Initial Raster checks

Goals - Establish beam to be roughly centered in beam pipe by locating it on YAG viewer just upstream of target. - Turn on Raster and verify beam profile expands as expected. Setup - Beam Current: Viewer limited (Tune Beam) - Target: No Target - Raster: Off; 5mm diameter

Procedure - Insert YAG viewer on Hall C superharp girder - start with raster off, verify beam spot roughly centered - if the beam energy has changed, check that on the Hall C Raster Control GUI it is initialized for the correct beam energy (at the top of the GUI). - request raster on: 5mm diameter - watch beam spot on viewer and verify Raster's basic functionality - Retract viewer

Harp scans/Bullseye scan (Brad and JP fix this)

Goals - Verify operation of Harp scanners w/ beam. - Establish acceptable beam profile (nominal 100--500um sigma)

Setup - Beam Current: 5 uA CW - Target: No Target - Raster: Off

Procedure - Verify that the raster is OFF for the harp scans at the target (3H07) - Ask for harp scans with IHA3H07A and IHA3H07B - verify beam profile (nominal 100--500um sigma) on at least one scanner on Hall C upstream beamline (good to check 3H07A/B)

Target/Beam centering, Raster calibration

Goals - Establish beam position on target, check/confirm raster size

Setup - Beam Current: 5-10 uA CW - Target: Double Carbon Hole - HMS setting: 12.5 deg, -2.4 GeV (electron W=2) - SHMS setting: 12.5 deg, -2.4 GeV (electron W=2)

Procedure - Note: DAQs should be running and double carbon hole target is in place - Online shift crew will proceed with program below.

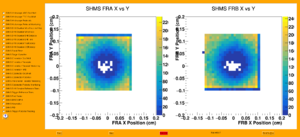

- Image Carbon Hole target using Raster current pickoffs vs. raw trigger rates in SHMS and/or HMS - Target: Double Carbon Hole - Current: 5 uA CW - Raster: 5mm diameter - Run DAQ on SHMS / HMS - Set prescales to ensure DAQ rate is dominated by scintillator triggers (ie. 3/4) - Run the online analyzer and look at the 'Fast Raster' panel of the online GUI: - Locate the hole in the 2D intensity histogram. A rough z cut should be included in the script to show up- and down-stream carbon hole separately. - NOTE: if the beam energy in standard.kinematics is not up to date, the distance scale on the 2D histogram will be wrong

- Center Beam on using Double-Carbon-Hole Target:

- Iterate until the hole is clear, and is centered in the circular raster pattern for both up- and down-stream carbon foils

- Adjust beam position

- Re-run the online analzyer on the new file(s) to see the effect of a raster size change and/or beam position change. Make sure changes are logged in the CODA start-run entries!

- Estimate raster dimensions against Carbon Hole diameter (known to be 1mm).

- Make sure we run at 5uA CW and run harp scan on target girder and verify width of the harp is consistent with 5mm diameter raster setup.

- To be discussed: should we adjust Raster magnet settings until raster an appropriate size (RC will know).

Target system checkout and commissioning

Goals - Make sure we can put beam on all targets. Raster should be ON (5mm diameter) for all settings. - This step also serves/completes the basic trigger/DAQ checkout, and tuning of online monitoring scripts. - Have a rough feeling for large ytarg optics.

Setup - Beam Current: 5-30 uA CW, raster always ON (5mm diameter) - HMS setting: 30 deg, -2.4 GeV - SHMS setting: 30 deg, -2.4 GeV - Target: Varies

Procedure - Move target to single foil position, take a 2 minute run at 5 uA and confirm we see one foil. - Keep target at single foil position, ask MCC to increase current to 30 uA for one minute, verify ramp rate is no more than 1uA/sec and that beam reach 30uA. - Move target to multi-foil position, take a 2 minute run at 5 uA and confirm we see all seven foil. - Fill reference cell with 1 atm N2, verify raster is really ON. - Move target to reference cell position, start a run at 5uA, increase current to 10uA, 15uA, 20uA, 25uA, and 30uA, stay 2 minute at each current setting. Look for the two glass windows at z=+20 and -20cm and verify target is still there.

Polarized 3He Cell checkout and commissioning

Goals - Make sure we can put beam on the polarized 3He cell. - This should also complete the commission of all target polarimetry. - Ideally we would like to determine beam depolarization effect and time constant.

Setup - Beam Current: 5-30 uA CW, raster always ON (5mm diameter) - HMS setting: 30 degrees, -2.4 GeV/c (electron) - SHMS setting: 30 degrees, -2.4 GeV/c (electron) - Target: Polarized 3He Cell - Target Spin direction: 0 or 180 deg - Target Coil Settings: TBD

Procedure - Ask the target operator to do one pNMR measurement. - Move target to polarized 3He cell position, take a 2 minute run at 5uA and confirm we see events from both 3He gas and two glass windows at z=+20 and -20cm. - Stop the beam, ask the target operator to do one target polarimetry measurement. - take a 10 minute run at 30uA, watch the beam ramp rate (confirm it is no faster than 1uA/sec), and confirm we see events from both 3He gas and two glass windows at z=+20 and -20cm. - Stop the beam, ask the target operator to do one target polarimetry measurement. (Note beam depolarization time constant is 3-5 hours so we will not see this.)

Detector checkout and calibrations

Goals - to verify PID detectors work properly

Procedure - Because we use 3/4 triggers, PID and ECal calibrations are not crucial at this stage. However, we can use data taken above to do a rough PID performance check for both the Cherenkov and the ECal.

Possible Moller (?)

- there is a desire to setup Moller and measure Pb at 2-pass but this is perhaps optional depending on D.G's confidence in his Moller.

Other

Goals - What to do if we have finished all above and there is still time left before pass change to 1-pass?

Procedure - We could possibly do optics calibration (need 15 hours total, sieve in). Ask RC!