Beam and Raster Checkout for A1n/d2n (Long Procedure)

From HallCWiki

Establish beam in the hall

Goals - Using "Target Out" location, make sure beam reaches beam dump without hitting anything.

Initial Raster checks

Goals - Establish beam to be roughly centered in beam pipe by locating it on YAG viewer just upstream of target. - Turn on Raster and verify beam profile expands as expected. Setup - Beam Current: Viewer limited (Tune Beam) - Target: No Target - Raster: Off; 5mm diameter

Procedure - Insert YAG viewer on Hall C superharp girder - start with raster off, verify beam spot roughly centered - if the beam energy has changed, check that on the Hall C Raster Control GUI it is initialized for the correct beam energy (at the top of the GUI). - request raster on: 5mm diameter - watch beam spot on viewer and verify Raster's basic functionality - Retract viewer

Bull's Eye Scan: BPM and Raster Calibration

Bull's Eye Scan Main Page Bull's Eye Scan: BPM vs Harp scan Calibration

Goals We want to be able to correlate the BPM ADC data with the "absolute" positions given by the surveyed Harp scanners for these nominal BPM positions: (0, 0), (+2,+2), (+2,-2), (-2,+2), (-2,-2)

NOTE: The positions above can be experiment specific. Confirm with RC.

Procedure

Starting Settings Beam: 5uA CW, Raster OFF Beam Position: (0, 0) Target: Carbon or 'No Target' Have a stripchart of the 3HO4A, 3HO4B, and 3HO4C BPMs visible. [Run go_beam_stripchart, if needed.]

Start an HCLOG entry titled 'BPM calibration' and record the following for each of the 5 (x, y) points above

- Requested Beam Position

- HMS/SHMS Run numbers

- Harp Scan log entries

For each of the 5 points identified above, do the following

- We want all BPMs to have (roughly) the same values for each point (so the beam is roughly parallel to the beamline). Tolerances of +-0.3 or so on the requested numbers are fine.

- Be sure the BPMs and beam are stable, start a CODA in each arm for a few minutes, then call MCC and request that they run and log a harp scan for both 3H07A and 3H07B to the HCLOG.

Just leave the CODA run going during the scans.

Submit your HCLOG summary table

- Make sure your table is complete

- Add a screen snapshot of the BPM stripchart

Harp scans

Goals - Verify operation of Harp scanners w/ beam. - Establish acceptable beam profile (nominal 100--300um sigma)

Note - We need sigma=100-300um. If sigma is larger than 300um, ask MCC to tune beam. If sigma reaches below 400um, call RC for advice on whether we should accept the beam.

Setup - Beam Current: 5 uA CW - Target: No Target - Raster: Off

Procedure - Verify that the raster is OFF for the harp scans at the target (3H07) - Ask for harp scans with IHA3H07A and IHA3H07B - verify beam profile (nominal 100--300um sigma) on at least one scanner on Hall C upstream beamline (good to check 3H07A/B)

Target/Beam centering, Raster checkout

Goals - Establish beam position on target, check/confirm raster size

Setup - Beam Current: 5-10 uA CW - Target: Double Carbon Hole - HMS setting: check run plan - SHMS setting: check run plan

Procedure - Note: DAQs should be running and double carbon hole target is in place - Online shift crew will proceed with program below.

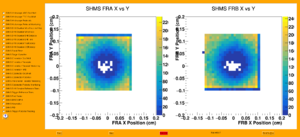

- Image Carbon Hole target using Raster current pickoffs vs. raw trigger rates in SHMS and/or HMS - Target: Double Carbon Hole - Current: 5 uA CW - Raster: 5mm diameter - Run DAQ on SHMS / HMS - Set PS1=0 and all other PS=-1 to ensure DAQ is dominated by scintillator triggers (i.e. "3scintillators out of 4" or "3/4" triggers) - Run the online analyzer and look at the 'Fast Raster' panel of the online GUI: - Locate the hole in the 2D intensity histogram. A rough z cut should be included in the script to show up- and down-stream carbon hole separately. - NOTE: if the beam energy in standard.kinematics is not up to date, the distance scale on the 2D histogram will be wrong

- Center Beam on using Double-Carbon-Hole Target:

- Iterate until the hole is clear, and is centered in the circular raster pattern for both up- and down-stream carbon foils

- Adjust beam position

- Re-run the online analzyer on the new file(s) to see the effect of a raster size change and/or beam position change. Make sure changes are logged in the CODA start-run entries!

- Estimate raster dimensions against Carbon Hole diameter (known to be 1mm).

- Make sure we run at 5uA CW and run harp scan on target girder and verify width of the harp is consistent with 5mm diameter raster setup.