Beam and Raster Checkout for A1n/d2n (Short Procedure)

From HallCWiki

Establish beam in the hall

Goals - Using "Target Out" location, make sure beam reaches beam dump without hitting anything.

Initial Raster check with YAG Viewer

Goals - Establish beam to be roughly centered in beam pipe by locating it on YAG viewer just upstream of target. - Turn on Raster and verify beam profile expands as expected. Setup - Beam Current: Tune Beam (Viewer limited) - Target: No Target - Raster: Off; 5mm diameter

Procedure - Call MCC to insert YAG viewer on Hall C superharp girder. - start with raster off, MCC should post a picture, verify beam spot roughly centered. - if the beam energy has changed, check that on the Hall C Raster Control GUI it is initialized for the correct beam energy (at the top of the GUI). - request raster on: 5mm diameter - ask MCC to post a video of the viewer. It should show beam spot on viewer expanding larger than raster off case, and the beam spot size should show a breathing pattern. - MCC will retract viewer after check is done.

- An example of what to look for can be found in https://logbooks.jlab.org/entry/3764451 - Another example posted in elog: https://logbooks.jlab.org/entry/3768480 - Here is an example of how to interpret the images on the YAG viewer: https://logbooks.jlab.org/entry/3749551 (taken during initial beam checkout in December 2019).

Harp scans

Goals - Verify operation of Harp scanners w/ beam. - Establish acceptable beam profile.

Note - We need sigma=100-300um. - If sigma is larger than 300um, ask MCC to tune beam. - Once sigma reaches below 350um, call RC for advice on whether we should accept the beam.

Setup - Beam Current: 5 uA CW - Target: No Target - Raster: Off

Procedure - Verify that the raster is OFF for the harp scans at the target (3H07) - Ask for harp scans with IHA3H07A and IHA3H07B - verify beam profile (nominal 100--300um sigma in peak 3) on at least one scanner on Hall C upstream beamline (good to check 3H07A/B) - One can go more sophisticated and calculate the beam size at the target, see algorithm in https://logbooks.jlab.org/entry/3768482

Check Beam Positions

Goal - Do this if nominal beam positions are already established.

Setup - Beam Current: 5 uA CW - Target: No Target

Procedure - With "No Target" position, ask for 5uA CW and verify beam position with established nominal position

Target/Beam centering, Raster checkout

Goals - Establish beam position on target, check/confirm raster size

Setup - Beam Current: 5-10 uA CW - Target: Double Carbon Hole - HMS setting: check run plan - SHMS setting: check run plan

Procedure - Note: DAQs should be running and double carbon hole target is in place - Online shift crew will proceed with program below.

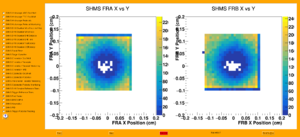

- Image Carbon Hole target using Raster current pickoffs vs. raw trigger rates in SHMS and/or HMS - Target: Double Carbon Hole - Current: 5 uA CW - Raster: 5mm diameter - Run DAQ on SHMS / HMS - Set PS1=0 and all other PS=-1 to ensure DAQ is dominated by scintillator triggers (i.e. "3scintillators out of 4" or "3/4" triggers) - Run the online analyzer and look at the 'Fast Raster' panel of the online GUI: - Locate the hole in the 2D intensity histogram. A rough z cut should be included in the script to show up- and down-stream carbon hole separately. - NOTE: if the beam energy in standard.kinematics is not up to date, the distance scale on the 2D histogram will be wrong

- Center Beam on using Double-Carbon-Hole Target:

- Iterate until the hole is clear, and is centered in the circular raster pattern for both up- and down-stream carbon foils

- Adjust beam position

- Re-run the online analzyer on the new file(s) to see the effect of a raster size change and/or beam position change. Make sure changes are logged in the CODA start-run entries!

- Estimate raster dimensions against Carbon Hole diameter (known to be 1mm).

- Make sure we run at 5uA CW and run harp scan on target girder and verify width of the harp is consistent with 5mm diameter raster setup. - For an example of complete beam centering procedure using carbon hole, see https://logbooks.jlab.org/entry/3749551