Beam Checkout Procedures

From HallCWiki

Jump to navigationJump to searchBasic Beamline, Raster, Instrumentation checkout

Initial Raster checks

Goals - Establish beam to be roughly centered in beam pipe by locating it on YAG viewer just upstream of target. - Turn on Raster and verify beam profile expands as expected.

- Beam Current: Viewer limited (Tune Beam) - Target: Empty, or solid target - Raster: Off; 2mm x 2mm

Procedure

- Insert YAG viewer on Hall C superharp girder

- start with raster off, verify beam spot roughly centered

- if the beam energy has changed, check that on the Hall C Raster Control GUI it is initialized for the correct beam energy (at the top of the GUI).

- request raster on: 2mm x 2mm

- watch beam spot on viewer and verify Raster's basic functionality

- Retract viewer

Harp scans

Goals -Verify operation of Harp scanners w/ beam. - Establish acceptable beam profile (nominal 100--500um sigma)

- Beam Current: 5 uA Tune Beam - Target: Empty, or solid target - Raster: Off

Procedure - Verify that the raster is OFF for the harp scans at the target (3H07) - Ask for harp scans with IHA3H07A and IHA3H07B - verify beam profile (nominal 100--500um sigma) on at least one scanner on Hall C upstream beamline (good to check 3H07A/B)

Target/Beam centering, Raster calibration

Goals - Establish beam position on target.

- Beam Current: 5--10 uA CW - Target: BeO, Carbon Hole

Procedure - Note: DAQs should be running and a solid target is in place - Online shift crew will proceed with program below. - We need to have a reasonably high (~1 kHz) trigger rate in at least *one* of the two spectrometers. It may be helpful to (temporarily) lower the spectrometer momentum setting and/or move the arm to a more forward angle.

- Attempt to view beam on BeO (if available in target ladder) ** NOT available in current target configuration (2017--2019) **

- Target: BeO

- Current: 5 uA CW

- Raster: OFF

- Target camera: ON

- Target lamp: OFF

- Log camera snapshot of beam spot on BeO

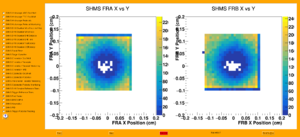

- Image Carbon Hole target using Raster current pickoffs vs. raw trigger rates in SHMS and/or HMS

- NOTE: If there are issues with the raster systems, this step can be skipped provided experts are confident that we know where the beam is on target

- Target: Carbon Hole

- Current: 5+ uA CW (Whatever is needed to achieve a reasonable 3/4 trigger rate in at least one arm.)

- Raster: 3mm x 3mm (Something significantly larger than the diameter of the hole in the Carbon foil.)

- Run DAQ on SHMS / HMS / COIN

- Set prescales to ensure DAQ rate is dominated by scintillator triggers (ie. 3/4)

- For the COIN DAQ, set the target rate for PS1 and PS3 to be 1000Hz, save the prescale values before starting a run

- Run the online analyzer (HMS/SHMS 50k scripts) and look at the 'Fast Raster' panel of the online GUI:

- For PionLT 2021, execute ./run_coin_hms.sh or ./run_coin_shms.sh, see here for more information

- Locate the hole in the 2D intensity histogram.

- NOTE: if the beam energy in standard.kinematics is not up to date, the distance scale on the 2D histogram will be wrong

- Center Beam on using Carbon-Hole Target:

- Iterate until the hole is clear, and is centered in the square raster pattern

- Adjust beam position

- Re-run the online analzyer on the new file(s) to see the effect of a raster size change and/or beam position change. Make sure changes are logged in the CODA start-run entries!

- Calibrate raster dimensions against (known, typically 2mm diam.) Carbon Hole diameter by adjusting Raster magnet settings until raster an appropriate size (RC will know).